Recently, the idea of the “Metaverse” has become very common in the technology and business worlds. It is no longer just something from science fiction stories. While many people talk about how the Metaverse is used for fun, socializing, cryptocurrency, and games, there is another important aspect: the Industrial Metaverse.

In this article, we will explore deeply what the Industrial Metaverse is. We will also look at its advantages, the technologies it uses, the challenges it faces, and how it could change different businesses and industries. Understanding the Industrial Metaverse can help companies see new ways to improve their operations and create new opportunities.

What Is the Industrial Metaverse?

The Industrial Metaverse is where virtual and real worlds come together in industries like making things, building, energy, healthcare, and transportation. Simply put, it creates digital copies, called “digital twins,” of real equipment, machines, and buildings.

Companies can then use these digital twins to study, simulate, and predict how things might work in these industries. Unlike the regular Metaverse, which focuses on many different activities like gaming and socializing, the Industrial Metaverse concentrates on specific industries. It uses its capabilities to make operations within these fields work better and more efficiently.

The concept of the Industrial Metaverse has several key parts that work together to achieve these improvements. Digital Twins are virtual copies of real-world objects, such as machines or factories. They act like the real objects in the digital space, mimicking how they work. Real-time Monitoring uses special sensors and devices to watch what is happening right now.

This helps to find problems early. Analysis tools look at all the information collected to find patterns and predict what might happen in the future within the Industrial Metaverse. Simulation involves testing different scenarios on a computer to see what could happen in real life.

This helps with planning without making actual changes in the real world. Optimization means making changes to improve how work flows. This could involve adjusting production schedules, using resources better, or implementing programs to predict when maintenance is needed in the Industrial Metaverse.

Benefits of the Industrial Metaverse

0Generally, the Industrial Metaverse can help companies operate more effectively in several ways. First, by using digital copies, organizations can improve their work processes. They can also prevent equipment breakdowns and use their resources wisely.

For example, digital twins can predict when machines might need repairs. They can send alerts so managers can fix issues before they cause problems. This saves both time and money for companies using the Industrial Metaverse.

Second, the Industrial Metaverse can make it easier for teams to work together, even if they are in different locations. Experts from various departments can examine machines and help solve problems without needing to be physically present.

This improves collaboration and speeds up problem-solving within the Industrial Metaverse. Lastly, it allows companies to test new ideas in a safe, virtual environment. Whether it is designing new products or trying out different possible situations, they can experiment without risking real money or safety in the Industrial Metaverse.

Challenges of Using Industrial Metaverse

Using the Industrial Metaverse also presents some challenges that need to be addressed. First, security is a major concern. For industries that handle a lot of sensitive information, such as healthcare, it is crucial to have strong security measures in place.

This ensures that unauthorized individuals cannot access private data within the Industrial Metaverse. Another challenge is compatibility. For large industrial companies that require significant power and resources to operate, it is essential to ensure that all the different components of the Industrial Metaverse can work together smoothly.

This prevents disruptions and ensures efficient operation. Lastly, there are important ethical questions to consider, such as how these technologies might affect the environment. The Industrial Metaverse consumes considerable computing resources and energy, raising concerns about its environmental impact and sustainability.

Technologies and Platforms Needed for the Industrial Metaverse

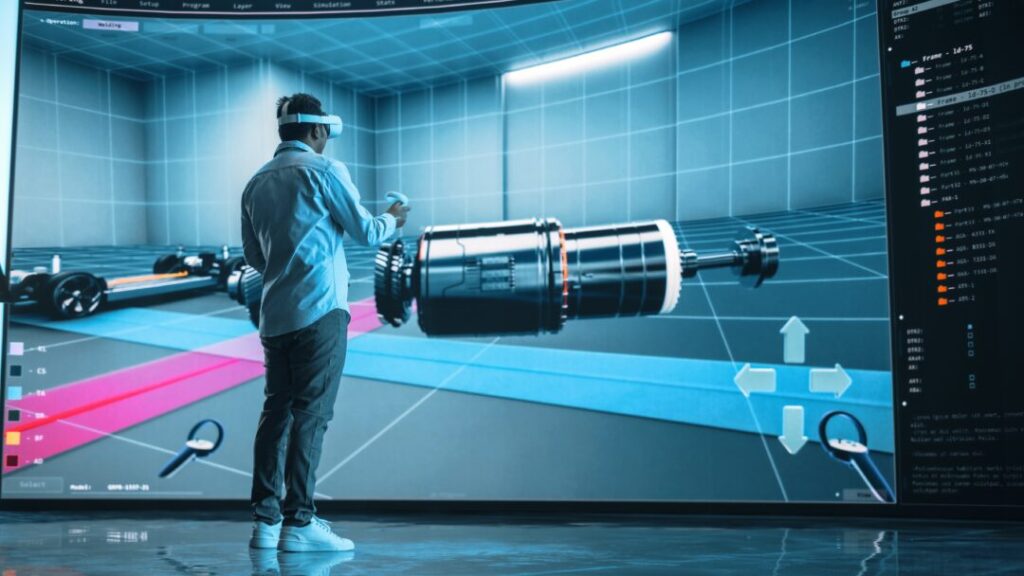

Building the Industrial Metaverse requires various technologies and platforms. These include Internet of Things (IoT) sensors, augmented reality (AR), virtual reality (VR), artificial intelligence (AI), blockchain, and more.

For example, augmented reality (AR) and virtual reality (VR) give users immersive experiences in the Industrial Metaverse. They can blend digital equipment into the real world or create entirely new virtual spaces.

IoT devices and wearables can collect real-time data from physical objects. This helps connect the virtual and real worlds within the Industrial Metaverse. Cloud computing is essential for managing the large amounts of data that these systems generate.

Artificial intelligence (AI) and machine learning (ML) help make sense of the collected data. This leads to better operational efficiency and even allows for automated decision-making in the Industrial Metaverse.

Blockchain technology ensures data security and transparency, especially for tracking goods through supply chains in the Industrial Metaverse. Collaboration tools enable people to work together effectively, even if they are in different physical locations.

Additionally, 3D modeling and simulation software are used to create and visualize virtual environments and objects. These are useful for tasks like testing designs or providing training within the Industrial Metaverse.

Potential for Business Across Different Industries

The Industrial Metaverse offers numerous opportunities for businesses across various industries. In manufacturing, it can aid in designing and testing products using virtual simulations.

This saves both time and money compared to building physical prototypes.

In logistics and supply chain management, the Industrial Metaverse can improve speed and accuracy by tracking goods in real time and using AI to find the best routes. In healthcare, it can facilitate remote check-ups and training through 3D simulations.

For construction and architecture, teams can collaborate more effectively and identify mistakes early using shared design tools in the Industrial Metaverse. Retailers can use AR to provide customers with personalized shopping experiences, which can increase sales.

Furthermore, in education and training, the Industrial Metaverse offers interactive learning environments that allow people to practice and acquire new skills. Overall, leveraging the Industrial Metaverse has the potential to drive innovation, improve efficiency, and enhance customer experiences.

Conclusion

The Industrial Metaverse represents a significant innovation for businesses operating in manufacturing, construction, energy, transportation, and other complex sectors. Through the use of digital twins, it becomes possible to create virtual representations of real equipment and processes.

Companies can then monitor these representations in real time, test various scenarios, and implement necessary changes before applying them in the real world.

Despite some current challenges and issues that still need to be resolved, the potential benefits of the Industrial Metaverse make it a promising direction for businesses seeking to optimize their operations and create new sources of revenue.

Are you looking for advanced Metaverse development services? Contact Progressive Robot today to discuss your project needs and elevate your digital presence to the next level within the exciting realm of the Industrial Metaverse.